Thermal spraying |

|

|

|

|

|

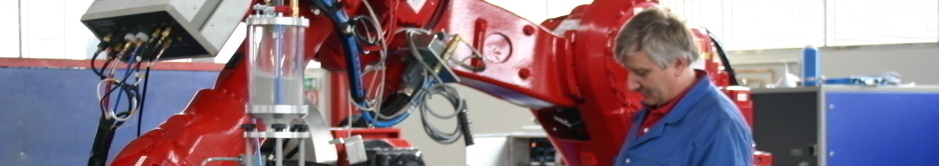

We offer the following facilities for this technology: |

|

|

|

|

|

|

|

|

|

|

|

Here are the key facts for all methods mentioned above: |

|

|

|

|

|

max. Ø: 1,400 mm |

|

|

|

|

|

Thermal spraying - process description: |

|

|

|

|

|

During thermal spraying the coating material (wire or powder) is fed to an autogenic or plasma flame, partially melts, is accelerated and applied to the workpiece. Lamination strength may vary between 0.1mm and 10 mm but most frequently lies between 0.2 mm and 0.8 mm. Hardness values can be achieved up to >1500 HV 0.3. Particle velocity varies between 80 m/s and 700 m/s according to the method used. Flame temperature also varies according to the method used and usually ranges from 2,800°C to 20,000°C. |

|

|

|

|

Advantages of this technology: |

|

|

|

|

Maximum workpiece temperature is only at 150°C despite such a high flame temperature. |

|

|

|

|

Resulting from this, there is neither warpage nor is any alteration in the microstructure to be found when this method is used. Another advantage of this technology is that any base material (steel, grey cast iron, aluminum, bronze, etc.) may be combined with any coating material (ceramics, carbide, stainless steel etc.). |

|

|

|

|

|

There are more than 100 different materials at your disposal to be used as coating materials. This method is primarily used with new parts, taking into consideration which coating to apply as early as in construction phase. Our principle is always “A cheap base material & a tailor-made surface”. This method is our choice in repairs and restoration of rejects, too. |

|

|

|

|

Typical applications: |

|

|

|

|

Coating material application |

|

|

|

|

|

· piston rods (tungsten carbide, chrome carbide) · Turbine components (tungsten carbide) · Faces of sealing elements (chrome oxide, chrome carbide) · Electrical insulation ceramics (aluminum oxide) · Electrically conductive copper, silver · Extruder screws (molybdenum) · Pump plunger (nickel-based resistant material alloy) · Ink ducts ceramics (chrome oxide, aluminum oxide) · Bearing surfaces (repair) (a variety of steel grades) · Hard chrome replacement (tungsten carbide, chrome carbide) · Special blends |

|

|

|

|

Finishing |

|

|

|

|

Finishing layers of resistant materials implies well-versed know-how. Finishing is usually performed by grinding by means of diamond or CBN discs. IMC Extrudertechnology accepts any orders from you to entirely finish your work. |

|

|

|

|

|

|

|

|

|

|

|

|

|