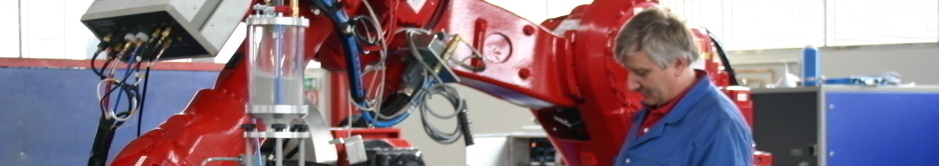

PTA welding |

|

|

|

|

|

PTA welding is done fully-automatically by a 12-axis robot. Here are the key facts: |

|

|

|

|

|

max. Ø: 3,500 mm Inside welding: from ø 50 mm to 3,000 mm length |

|

|

|

|

|

PTA welding - process description: |

|

|

|

|

|

During PTA welding the surface of the workpiece is partially melted by a plasma arc used as heat source. The weld consumable is supplied by a carrier gas. |

|

|

|

|

|

Advantages of this procedure: |

|

|

|

|

|

We also offer any other standardized welding (TIG welding, MAG welding etc.) in our facility. |

|

|

|

|

|

The advantages of this procedure are a low fusion degree (ca. 5%) and a small heat affected zone. Machining allowances are considerably lower than in other welding processes. Lamination strength may be very much smaller (> 1mm). Additionally, we offer a wide range of materials including tailor-made powder blends. |

|

|

|

|

|

Weld consumables are divided into three categories: |

|

|

|

|

|

· Iron-based alloys (e.g. 1.4571, 1.4313, Tristell) · Cobalt-based alloys (e.g. Stellite, Tribaloys) · Nickel-based alloys (with or without tungsten carbides) |

|

|

|

|

|

Typical applications: |

|

|

Weld consumable application |

|

|

|

|

|

Guide bushes (Stellite) Moulds for the plastics industry (nickel-based alloy) Forging dies (Stellite) Extruder screws (nickel-based alloy with tungsten carbide) Spherical valves (Stellite) Sealing surface of wedge gate valve plates (Stellite) Diverse parts of the chemical industry (Hastelloy) |

|

|

|

|

|

|

|

|

Finishing |

|

|

|

|

|

Finishing layers of resistant materials implies experience therein and special tools. IMC Extrudertechnology accepts any orders from you to entirely finish your work. |

|

|

|

|

|

|

|